So, what is the difference between brass and bronze? Although brass and bronze have copper (Cu) as their common primary element, they are not the same. Their composition, properties, uses, and sometimes colors differ from each other. So, it is important to learn how to differentiate them. In this article, you will learn about the properties and uses of brass and bronze. You will also know the difference between these two alloys and identify them.

Introduction to Brass

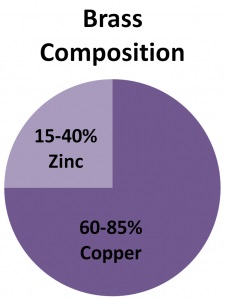

Brass is a metal alloy. It contains more than one or two different elements. In most cases, brass comprises copper (Cu) and zinc. It can also have a mixture of metals other than zinc, like tin or lead in them. So, brass has mainly three forms- copper-zinc brass, tin-brass, and lead brass. Nowadays, iron (Fe), aluminum, tin (Sn), manganese (Mn), Nickel (Ni), and silicon (Si) are mixed in the combination of brass for various purposes. Bronze mixes with other metals easily. Thus, it has many uses. Some common types of brass are:

Yellow brass Red brass 330 brass 360 brass 464 brass

Brief History of Brass

Although the brass, as we know, was invented in the 18th century, it was originally introduced in about 500 BC. Back then, zinc was not available in its natural state. But the people mixed calamine with copper. Calamine is a zinc ore; hence, the brass was not like modern brass. However, it was still useful in many ways. Brass had a high melting point but was malleable. The Romans used brass in making coins, artifacts, jewelry, vessels, dress armor, brooches, clasps, etc. In modern times, zinc is used to produce brass instead of calamine. The amount of zinc influences the strength and ductility of brass. The higher the amount of zinc is, the more durable brass gets. Besides, the color range of brass changes from red to yellow based on the amount of zinc.

Characteristics of Brass

Brass has some unique characteristics. It is important to understand the characteristics to know how to use brass. • Most brasses are dull gold or yellowish, depending on the amount of zinc. • The low melting point of 810-1000 degrees C. Hence, can be cast into molds. • Brass has high malleability because of copper. • It is corrosion-resistant. Brass containing manganese is highly corrosion resistant. • Low electric conductivity and above-average thermal conductivity. • Brass has some antibacterial properties.

Uses of Brass

As brass is malleable, it is easy to shape and size for various purposes. From household to industrial use, brass has many applications. • Decorative Use: The color can range from copper red, golden to silver, depending on the amount of zinc and copper. The unique color of brass makes it a great material for decorative items. It is used as dishware, lamp fitting, locks, door handle, bathroom fixtures, cabinet hardware, furniture, etc. Brass is often used to create amazing statues and sculptures because the metal is quite flexible. Many countries also have brass coins. • Musical Instruments: Brass is an excellent alloy for making musical instruments. It is corrosion-resistant and pleasant to the eyes. Above all, it affects the tone of musical instruments. Some popular instruments made of brass are trumpets, trombones, French horns, tubas, and baritones.

• Mechanical Applications: Brass is used widely as mechanical parts for various applications. It is found in gears and bearings. You can also see brass casing for rifles and guns. The properties of brass make these things long-lasting. • Marine use: As brass is highly corrosion resistant. Therefore, its use extends to making boat snaps, fasteners, pulleys, and swivel eye bolt snaps. • Plumbing Pipes and Tubing: The hardness, durability, and corrosion-resistant properties make brass perfect for plumbing pipes, tubes, and other tools.

The Basics of Bronze

Bronze is one of the most popular metals in the world. It is also a copper-based alloy. Pure bronze consists of 88%-90% copper and 10%-12% tin. However, you will also find bronze containing arsenic, lead, aluminum, silicon, magnesium, nickel, and phosphorus for different use of the metal. The combination of such metals makes bronze stronger than copper. Some common types of Bronze are:

Aluminum Bronze Lead Bronze Phosphor Bronze/ tin bronze Silicon Bronze Manganese Bronze Copper Nickel

Brief History of Bronze

Bronze has been used long before brass was invented. There is evidence that the ancient Sumerians started using bronzes around 3500 BC. Once the people learned how to produce bronze, the alloy spread from Mesopotamian cities to Persia. It was so widely used that historians named a historic period (3300 BC to 1200 BC) the Bronze Age. Before bronze, copper was used for various purposes. However, when people realized bronze is much harder and more durable than copper, they used it for daily and special uses. The ancient craft workers of the era used bronze to produce various tools and weapons. Bronze was also used for making vessels, statues, ornaments, utensils, fittings for chariots, and so on. Today, the use of the alloy has extended to many fields, such as electrical and technical parts.

Characteristics of Bronze

Here are some characteristics of bronze. You will see the difference from brass in these features: • Bronze can be reddish-brown to a dull golden color based on the elements it has. • Like brass, bronze is also highly ductile. • It is hard and can be brittle (less than cast iron) because of excessive stress. • The melting point of bronze is about 950-1080 degrees C. • The alloy has high corrosion resistance against seawater. • Since it has copper, bronze is also malleable, but not as much as brass.

Uses of Bronze

When bronze is melted, it can be molded into various shapes. It is also compatible with many other metals. Bronze has endless uses. Here are some common uses of the metal we see daily: • Art and Decoration: Since ancient times, bronze has been used as a material for creating sculptures and decorative items. Bronze has a unique feature of expanding after cooling down. Similar to brass, it is also easy to work with. The heaviness and density of the metal help artists to create fascinating statues and decorations. • Construction tools: Bronze is a common metal for making constructing tools like hammers, wrenches, mallets, bolts, and many gears. They are not as sparky as steels, so have less possibility of causing fire during construction. Some constructions, like movable bridges, also require some type of bronze.

• Electric and Mechanical Parts: Bronze is a must element in building many parts of electric and mechanical products. It has high electric conductivity, low friction, and good thermal conductivity. Thus, bronze is safe to use in gears, bearings, bushings, valves, springs, and different parts of engines. • Musical Instrument: Bronze is heavily used in some popular music instruments like piano and guitar. The strings of these instruments are made of bronze for great tuning and durability. Bells are also made of this alloy. • Marine and Fishing: Bronze is resistant to saltwater. Therefore, many ships and boats have bronze in their propellers and fittings. The tools for fixing boats are also made of this alloy.

Brass Vs Bronze: A Detailed Comparison

As you can see, brass and bronze have some similarities and some differences. Let us compare these two metals to find out about them.

Elements of Brass and Bronze

The biggest difference between brass and bronze is their elements. Although both metals have copper (Cu) as the key element, the other element varies. In comparison, bronze has more copper than brass. Typically, modern bronze has 88% copper, and brass has 67% copper. Most brass has copper and zinc. But depending on the use, it may also contain the following elements:

Aluminum Iron Magnesium Silicon Tin Sulfur Phosphorus Lead Nickel Antimony

On the other hand, generally, bronze is a combination of copper and tin. But it can also have various elements as below:

Lead Aluminum Phosphorous Silicon Sulfur Manganese Cobalt Chromium Nickel

As you can see, some of the secondary elements of both alloys match. However, they do not exist in the same amount in brass and bronze.

Color of Brass and Bronze

Now, let us talk about the color differences of both alloys. As both brass and bronze have copper as their main element, they have a somewhat similar color. Most brass has muted yellow color or dull golden color. The color can change shades depending on the density of zinc and other elements mixed with copper. Bronze can also be dull golden. Therefore, some people think it is brass. However, most of the time, bronze has a reddish-brown or reddish-golden hue. You may also see faded stipe marks on the surface. Same as brass, the color can slightly change because of the properties of the elements.

Corrosion Resistance

Brass and bronze are corrosion resistant against saltwater. The level of resistance can differ. Brass is highly corrosion-resistant, but it eventually faces corrosion. Then it goes through the process of dezincification. When it happens, brass loses the zinc, and only the copper remains. Thus, the color of brass becomes pink. The corrosion on bronze is not the same. When it comes in contact with air, it oxidizes because of the copper. As a result, bronze develops a patina coating on the surface. This coating is harmless and actually protects the metal from corroding. However, bronze will corrode slowly if it comes in contact with chlorine compounds. The copper of the bronze gradually degrades.

Thermal Conductivity and Electric Conductivity

Copper and aluminum have the highest thermal conductivity. So, you may think both brass and bronze also have the same high thermal conductivity. However, as they are alloys, they have above-average thermal conductivity. If we compare brass and bronze, it is seen that brass has higher thermal conductivity than bronze. The same is more electric conductibility. Although copper is used for its high electrical conductivity, its alloys are not. As brass and bronze contain other elements besides copper, their electric conductibility is not as high as copper. Again, brass has better electric conductivity (28%) than bronze (15%). Both are used in electronics and machines. Check out the detailed article on does brass conducts electricity.

Hardness and Formability

You may wonder which of these metals is stronger or harder. This is determined mostly by the tolerance level of the metals, like how it bends, gets scratched, or break. Bronze is typically harder than brass. Thus, bronze can brittle more than brass. Based on Brinell’s measurement of hardness, it is 55-73 for brass and 40-420. If you want to know which one is stronger, then it is bronze. But bronze is not easily malleable like brass. Brass is more manageable to work with even if it is not as hard as bronze. Brass is softer. So, it is easier to cut, size, and shape.

Melting Point

The melting point of the metals is another important factor to compare. It is essential to learn the melting point of alloys to check their purity. Besides, you may want to stop heating before the melting point to shape the metals. Depending on the elements, the melting point of brass can be 810 degrees C to 1000 degrees C. For bronze, it can be 900 to 1080 degrees C. At the melting point, brass and bronze turn into their liquid form. Hence, they can be easily cast into preferable shapes and sizes. It is also seen that bronze expands once it cools down.

Durability

Considering the durability of bronze and brass is also crucial for choosing one for use. For something to last long, the materials have to be durable. Bronze is harder than brass and is not so flexible as brass. But this property of bronze makes it more durable than brass. You do not have to be too concerned about taking care of bronze daily. It can effectively handle moist and rough use. Besides, it takes a lot of time to corrode. Brass is also durable but not as much as bronze. Also, it corrodes faster compared to bronze, which means brass items need to be properly maintained. Hence, use bronze instead of brass if you can for any project.

Weldability

Brass and bronze are malleable copper alloys. Thus, they are also weldable. Then again, the ease of welding an alloy depends on its elements. For example, brass containing lead is difficult to weld while brass containing a little amount of zinc is quite weldable. Brass with 20% zinc has great weldability, and brass with more than 20% zinc is called fairly weldability. Bronze is also fairly weldable except for the lead bronzes. But during extreme stress, bronze can crack. So, it is crucial to be careful. Both brass and bronze can be welded together.

Machinability

When you use a metal, you may have to turn, mill, bend, stamp, and do some other actions to the metal. But not all metals can withstand the extreme process. Hence, it is necessary to know the machinability of any metal. Metals that have a 100% machinability rating are easy to process. On the other hand, metals below 100% are difficult to machine. Now, bronze has average machinability of 33%. And brass has 46.8%. Therefore, it can be guessed that brass and bronze do not have much machinability. Luckily, there are specially developed metal alloys of brass and bronze that can be machined easily.

Price Difference

A few factors determine the price of brass and bronze. Bronze is typically costlier than brass. The production process of bronze is the main reason for that. Also, the amount of copper used in the metal is a crucial factor for the pricing. Besides, bronze is harder than copper and brass. As it is more durable and sturdy, it is pricier than brass.

How to Identify Brass and Bronze?

Now that you have learned about the distinctive features of brass and bronze, you can differentiate between brass and bronze. It is not much of a problem to identify the color of the metals when they are new. But old bronze or brass metal can get discolored because of the dark green coatings over them. First, you need to clean the metal to bring back the former color. For thorough cleaning, you can make a homemade solution by mixing salt and vinegar. Make a thick paste with salt and vinegar and apply it to the metal. Use a sponge to scrub the metal. Then wash and dry the metal. Next, check the color of the metal. Bronze will have a reddish-brown or reddish-golden color. You will know it as a large amount of copper. Moreover, bronze often has faded marks on the surface. But if the metal has a dull yellow or golden color with no marks, it is brass.

Conclusion

Hopefully, you have gotten a clear idea about brass vs. bronze. There is no way to tell which one is the best because both are useful and necessary in their own way. They might have copper in them, but they are still unique. If you need to choose one for a new project, check out their characteristics to find out which one is better for the job. Happy learning!!